About Us

Quality Initiatives

Quality Assurance

Technology Initiatives

- Computerized environment provided for design, planning, store and accounts.

- A fully automated setup along with monitoring at personal levels.

- Fully documented inspection and testing procedure with 100% quality check

Production Setup

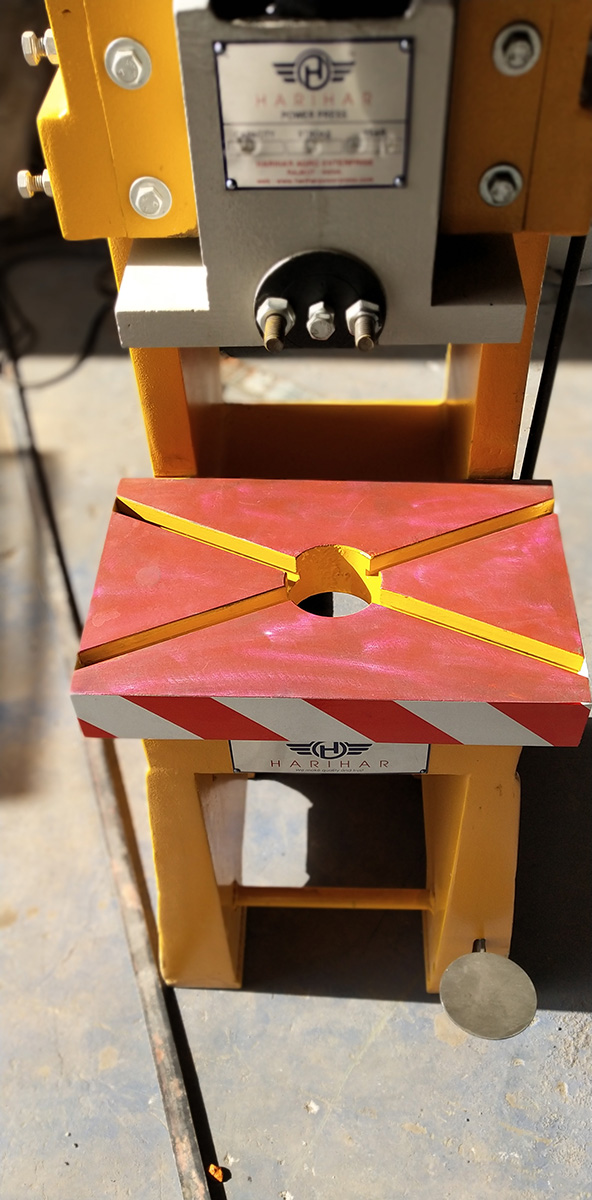

Frame

The frame is of all steel construction, fabricated from Rolled steel plates with suitable cross

ribbings. Presses Up to 30T will be supplied with C.I. legs. Proper alignment of the frame is

ensured by machining

Clutch

The clutches of pin/rolling key-type. The clutch is rigid and well supported. The clutch gives

continuous Strokes for mass production.

Crank Shaft

Crank shaft is made of special alloy steel machined to close accuracy and fitted in bronze

bushes for Smooth working, longer life & accuracy.

Flywheel

Properly sized Flywheel is made of high grade cast iron, for storing and releasing adequate

energy For the pressing operations, and properly balanced for smooth running.

Gears

Gears are of steel cast or fabricated. Gear teeth are generated by precision hobbing

machine

Table & Ram

Table and Ram are made of high grade heavy duty cast iron & properly seasoned. They are

perfectly Aligned, to each other to obtain high accuracy & precision press operation.